3D Printing Lx

Passionate about 3D Printing

-

No Compromise

We don’t cut corners, out motto is

“Quality, or No Deal”.

-

Personalized Solutions

Experienced Mechanical Engineer ready to develop and fabricate solutions re armless of the application.

-

The Sky's the Limit

With a vast array of materials, multi-material capabilities coupled with our knowledge and experience in the field, our solutions surpass expectations.

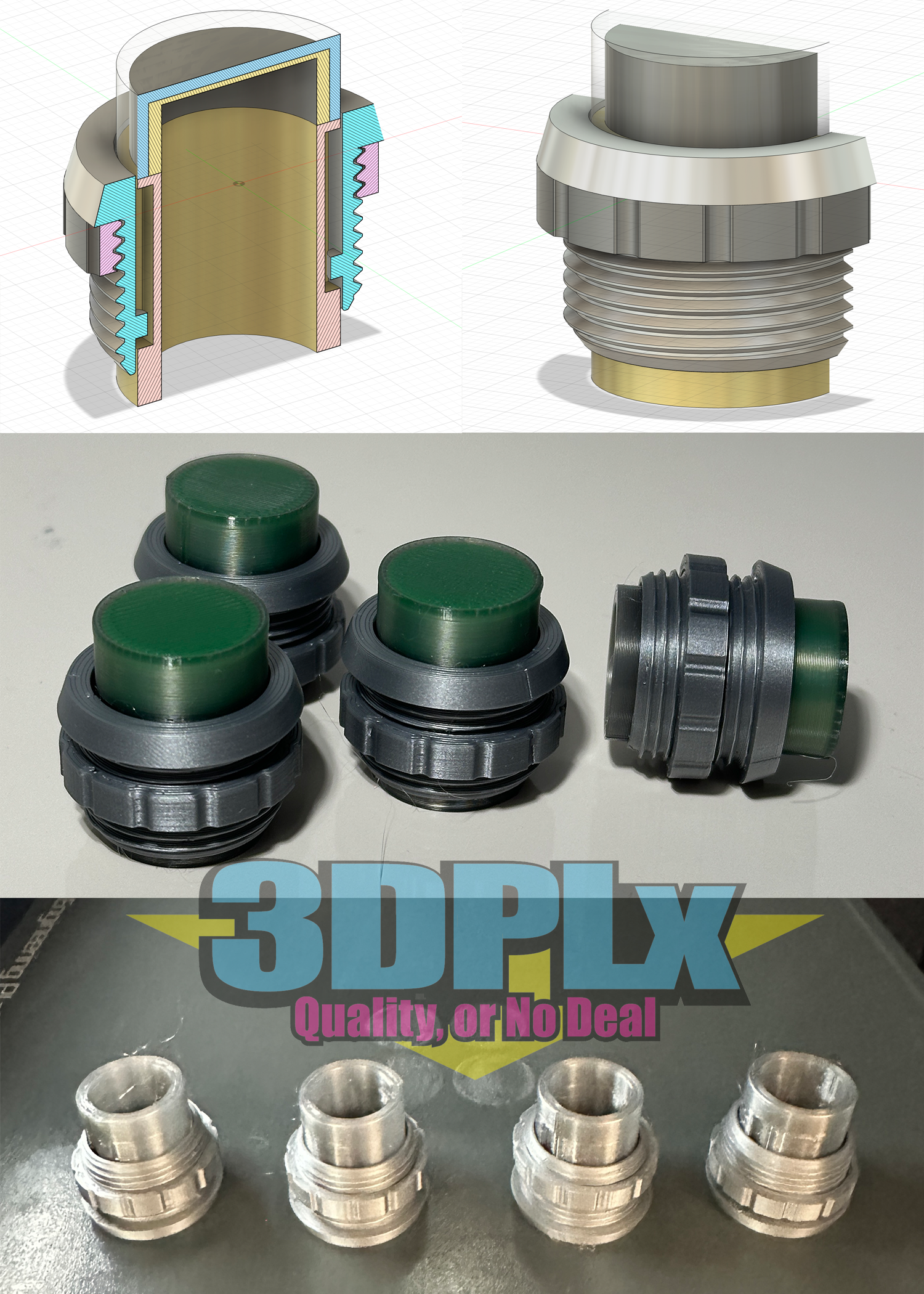

Personalized Buttons for antique elevator multi-material in PC, ABS & PLA (in-house design)

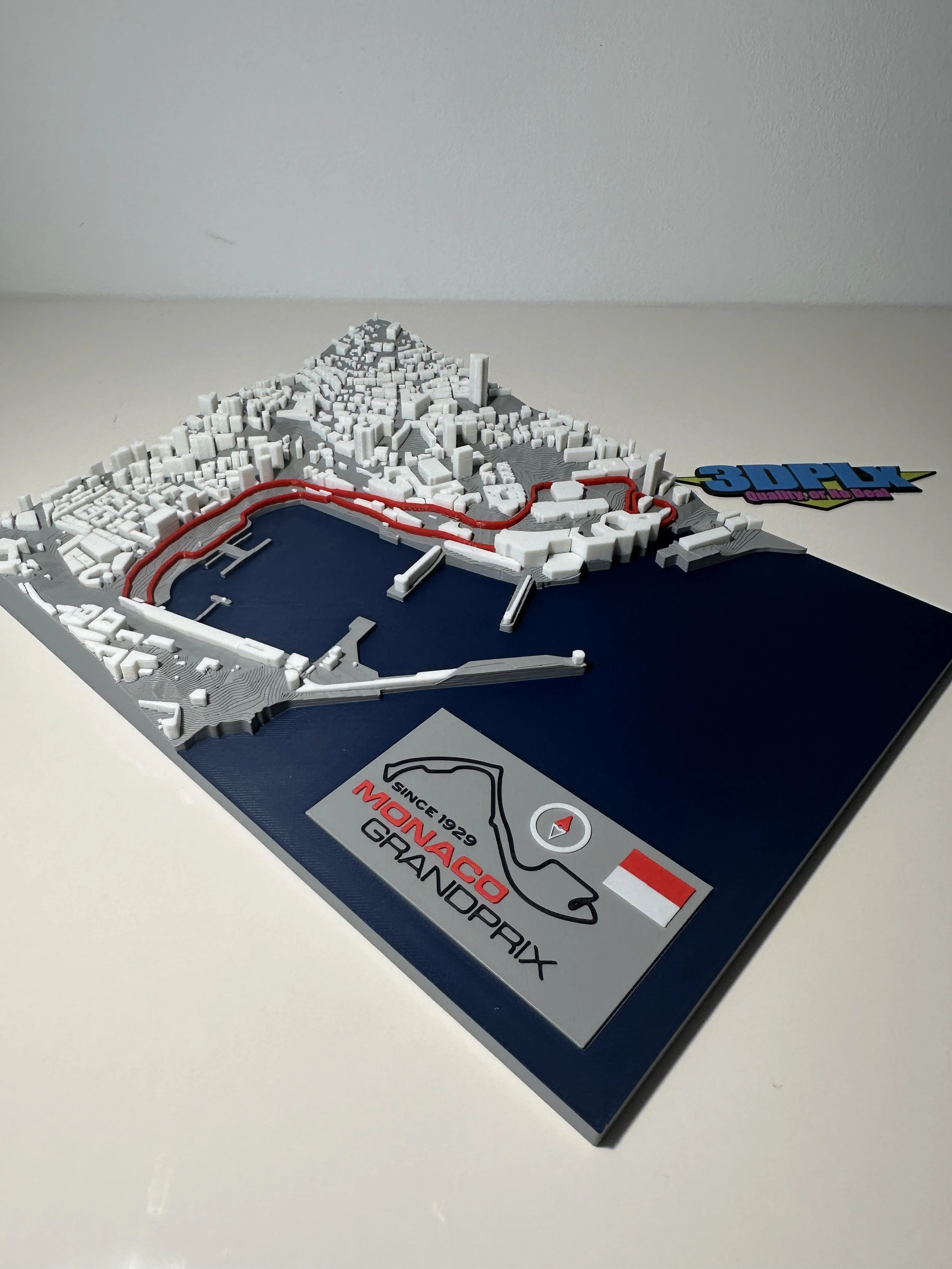

Monaco GP em PLA multicolor (design interno)

Pieces for Curta Calculator Scale Build by mwu in PLA & ABS

Circuit de Spa-Francorchamps in PLA multicolor (in-house design)

Custom Sail Guards for Sail Boat in ASA (in-house design)

Custom Keychains in PLA multicolor (in-house design)

Custom Desk Lamp in PLA (in-house design)

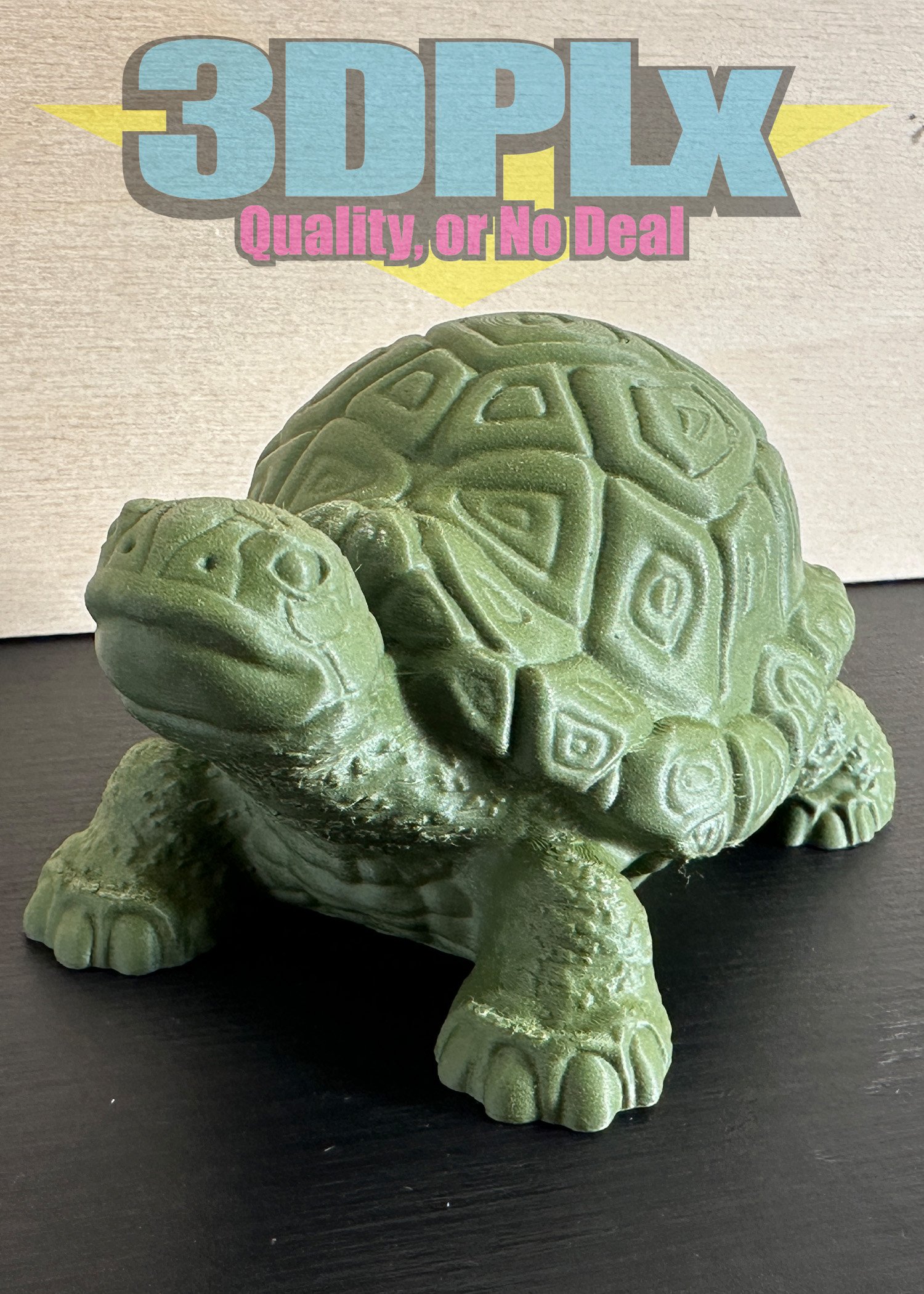

Turtle by Jipcutter in PLA with .12 mm layer height

Custom Pen Holder in ABS (in-house design)

Red Bull Ring in PLA multicolor (in-house design)

Decorative pieces in PLA

Custom outlet strip and device station in PLA (in-house design)

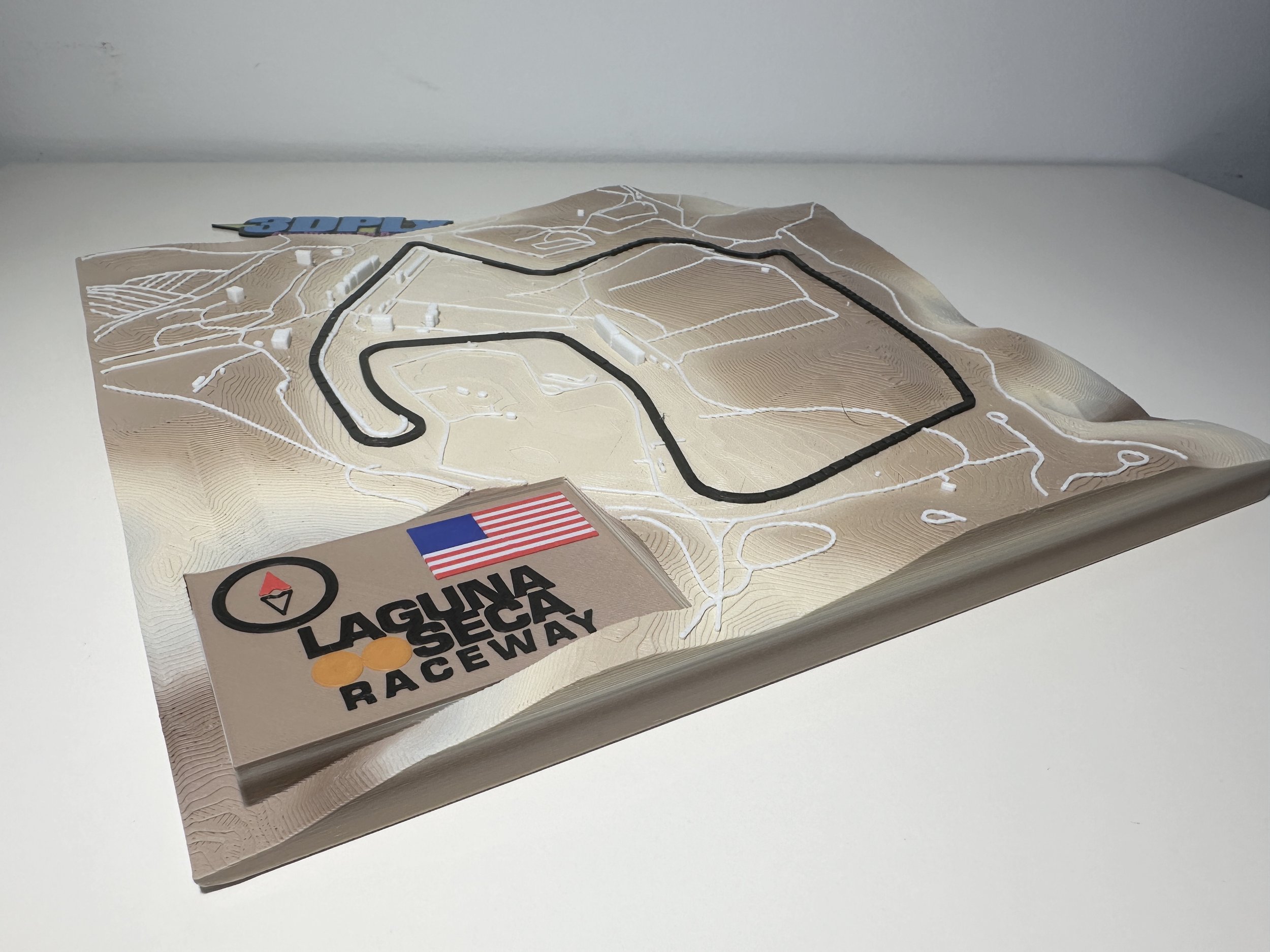

Laguna Seca in PLA multicolor (in-house design)

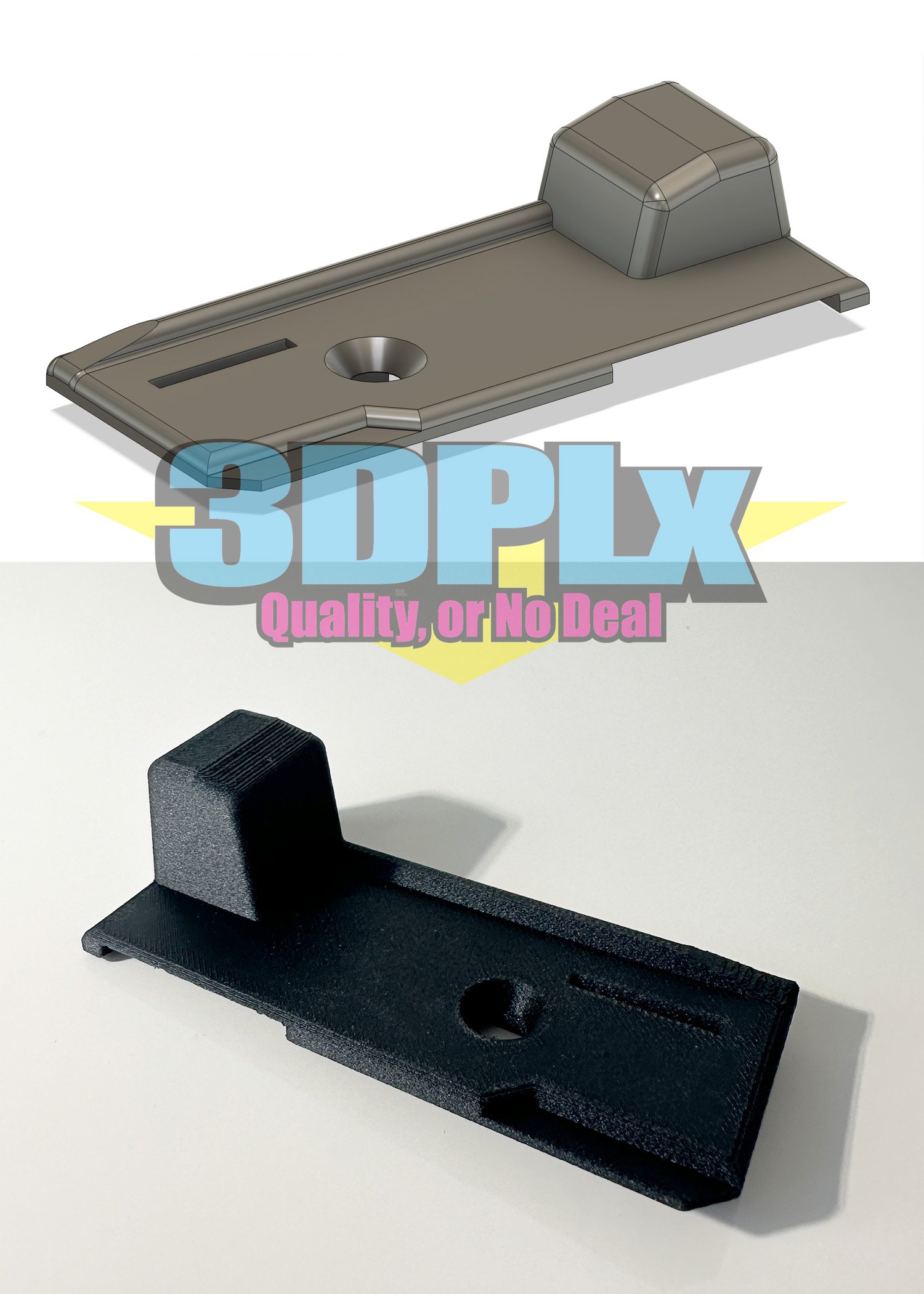

Custom Hotend case in PLA (in-house design)

Rocket by Mech-G in PETG transparent with .56mm layer height using spiral vase mode

Sail-Guard & VW buttons in ASA using Support-Material

Variety of colors, materials & 3D printing parameters

Paper bag by breuni in PAHT-CF with 0.56 mm layer height using spiral vase mode (single perimeter)

Nürburgring Nordschleife in PLA multicolor (in-house design)

BMW Motored part (in-house design) in PAHT-CF using Support-Material

Paper Bag by breuni in PLA using spiral vase mode (single perimeter)

Clamp by Prusament in PETG Transparent

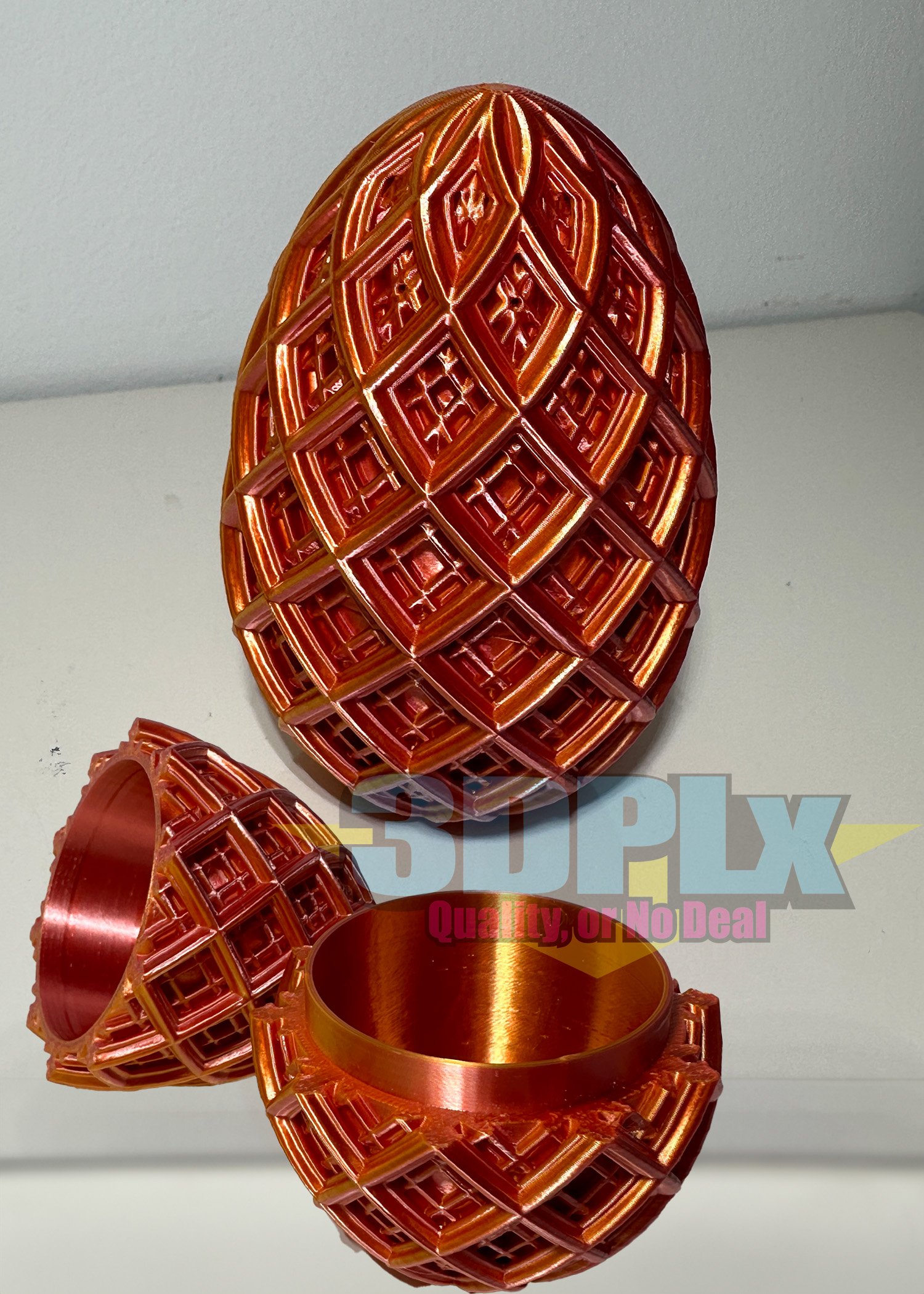

Easter Egg by Dazus in PLA Silk Dual Color

Small automotive gears in Nylon (PA) & ABS (in-house design)

'OREO' Container by M_D_K in PLA

Star Wars Unlimited Game Card and Chip tray in PLA

Nürburgring Nordschleife in PLA multicolor (in-house)

Jeep Kit Card by agepbiz in PLA multicolor

Silverstone Race Track in PLA multicolor (in-house design)

Torre de Belem in PLA

Decorative Pieces in PLA, PLA-CF & ABS

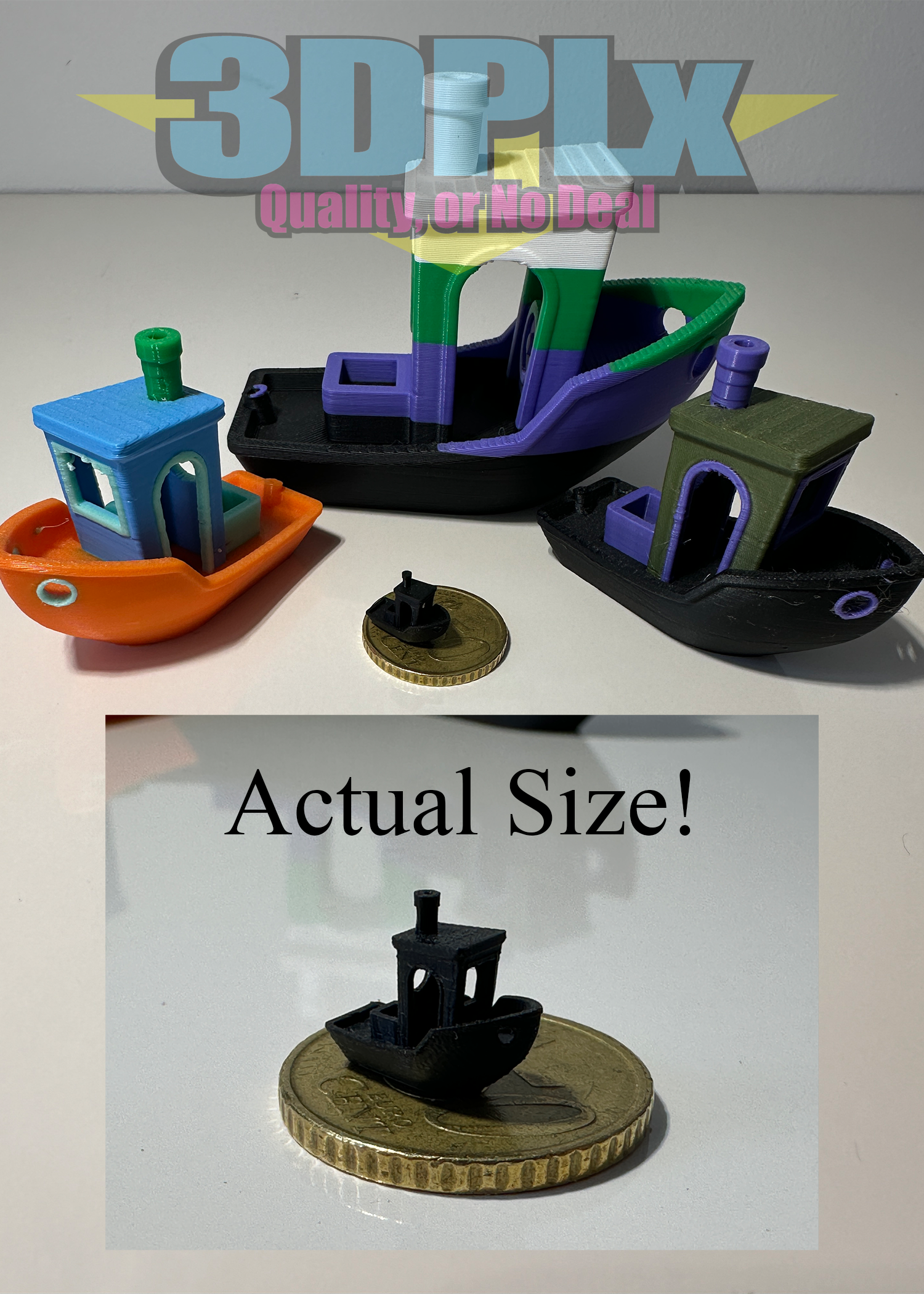

Benchies & Miniature in PLA & ABS multicolor

-

Cutting-edge machines and over a decade of knowledge and experience enable us to make designs and 3D Prints of premium quality and unbeatable turnover times.

-

Versed in 23 & 3D Design to fulfill your needs. We work with Fusion360, AutoCAD, Illustrator & Blender among other CAD and design softwares.

-

Consulting, finite element analysis, design and manufacture among other services available.

Services

Materials

-

(Polylactic Acid)

Properties: Biodegradable, environmentally friendly, offers good detail and print quality.

Applications: Ideal for prototypes, non-functional models, and decorative objects due to its low resistance to heat and chemicals.

-

(Lightweight PLA)

Properties: Similar to regular PLA, but lighter and more foam-like, providing better thermal and acoustic insulation.

Applications: More suitable for RC airplanes, drones, and parts where weight is critical without compromising structural integrity.

-

(Polyethylene Terephthalate Glycol)

Properties: Good balance between print quality and performance, durability, strength, chemical resistance, food safety, and safety for human contact. It is slightly flexible and can be translucent.

Applications: Perfect for functional parts that require strength, such as mechanical parts, containers, and outdoor applications.

-

(Acrylonitrile Butadiene Styrene)

Properties: High durability, heat resistance, and impact resistance.

Applications: Ideal for manufacturing end-use parts, automotive components, and anything that requires structural strength and durability.

-

(Acrylonitrile Styrene Acrylate)

Properties: Similar to ABS, but with improved UV resistance, making it less susceptible to weathering.

Applications: Suitable for outdoor applications, such as exterior automotive parts or garden equipment that require durability and resistance to the elements.

-

(Thermoplastic Polyurethane/ Thermoplastic Elastomer)

Properties: Flexible, durable, and resistant to abrasion and impacts. It can vary in terms of flexibility.

Applications: Used for parts that require flexibility and durability, such as phone cases, flexible joints, or wearable devices.

-

(Polyamide/Nylon)

Properties: Known for its strength, flexibility, and high resistance to wear and chemicals.

Applications: Ideal for functional parts subjected to mechanical stress, such as gears, hinges, or automotive components.

-

(Polycarbonate)

Properties: Offers excellent strength and heat resistance, and can be transparent.

Applications: Suitable for bulletproof glass alternatives, protective equipment, and parts that require high strength and temperature resistance.

-

Carbon Fiber or Fiberglass Reinforced Filaments

Advantages: Enhanced dimensional stability, exceptional mechanical properties, and a premium surface finish.

CF: PLA-CF, PETG-CF, PA6-CF, PET-CF, PAHT-CF

GF: PA6-GF

Other materials available upon request.

Contact Us

We Transforma ideas into solutions. Whether for hobbies, commerce ou industry, we are here to help. Tell us your needs and we will make a diference.

tf: +351 911933303 (SMS/iMessage/WhatsApp/Call)

E-mail: Exactprecision@protonmail.com

Send files >10MB by e-mail to: Exactprecision@protonmail.com